|

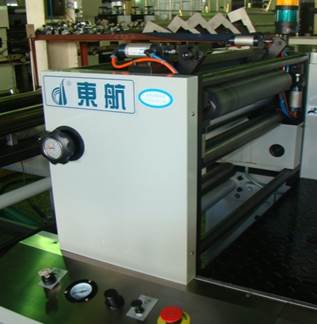

Спецификация Флексографской печатной машины горизонтального построения серии DH,

Max unwind unit diameter 1016mm Pneumatic mandrel unit diameter 3 " 1 unit Hydraulic roll shaft lift 1 unit Magnetic brake system 1 unit Automatic stopping device when paper broken Equipped with the fast speed pneumatic gun 2. Автоматическая система контроля и равнения края полотна флексографской машины DH

Splicing table and pneumatic paper pressing equipment 1 unit Adopts ball screw electric actuator Adopts the photoelectric sensor for web guide transmission Electronic web guide traction device. If there is any excursion in paper feeding, the system will have a constant and accurate adjustment. Adopts closed-loop control system to accurately detect the deviation and correct it. Hard anodization to the paper guide rollers HV800-1000 Inspection: the edge Web guide precision: ±0.02mm Use the double side pressure glue roller to clutch and feed and to guarantee the stable tension 4. Печатные секции флексографской машины DH

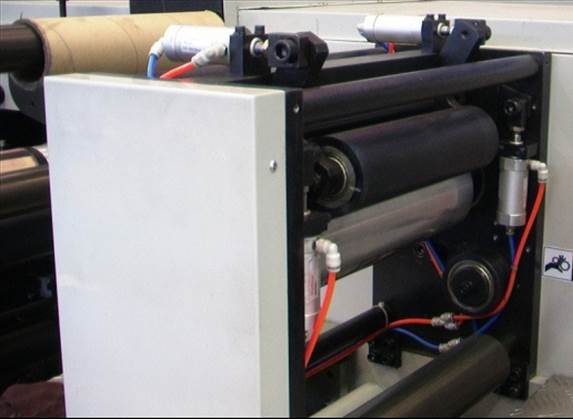

8 printing plate cylinders (repeated length at customer's need) 8 anilox rollers (LPI is according to the customer's products) Automatic vertical register (following the first color) Horizontal register by manual Anilox roller and plate cylinder with pneumatic clutch pressure which can quit automatically Plate cylinders can be changed without any other tools Automatic cleaning for printing plates Anilox rollers will continue running after the machine stops to prevent the ink from drying Anilox rollers equipped with high precision fine tuning system can make sure the pressure between anilox rollers and also plate cylinders Dance of anilox, plate cylinder and impression cylinder: ^0.01mm Bearings are P5 degrees

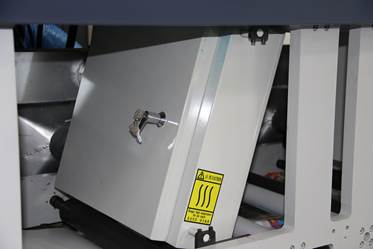

5. Сушки флексографской машины DH (количество сушек равно количеству печатных секций)

Hot air and cooling air combination (including blower) Volume of air can be adjusted Tubes from teflon in Korea There are one air induced draft fan and eight blowers Waste air will be out by an exhaust fan 6. Система видеоконтроля печати со стробоскопом флексографской машины DH

Image inspecting camera can take pictures synchronously for the printing materials. Preset the inspecting position horizontally and vertically. Zoom the images to have a position inspection. It can magnify 20 times and observe the image with a fixed position to guarantee the printing quality. Installed support equipment and cables High resolution camera

Use the double side pressure glue roller to clutch and feed and to guarantee the stable tension. 8. Система намотки полотна флексографской машины DH Max unwind unit diameter 1016mm Pneumatic mandrel unit diameter 3 " 1 unit Hydraulic roll shaft lift 1 unit

Magnetic brake system 1 unit Automatic stopping device when paper broken Equipped with the fast speed pneumatic gun 9. Системы чистки полотна, снятия

статики и коронирования флексографской машины DH

The automatic lubricating system is adjustable for the lubricating time and amount. When the system is wrong or it falls short of oil, the alarm light will work. 11. Система наклейки флексографской печатной формы для флексографской машины DH

It has a screen including the bilateral symmetrical split-screen display It is used for the plate mounting to realize the purpose of multi-color overprinting. Quickly changes the printing plates 12. Набор инструментов флексографской машины DH

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Высечное

Высечное